MIL-PRF-28750F

APPENDIX B

B.3.3.2.3.1.1 Sample size. The sample size shall be at least 10 dice from each wafer lot.

B.3.3.2.3.1.2 Subgroup 1 (Internal visual). Each sample shall be visually inspected after assembly for conformance

with the applicable die related requirements of MIL-STD-883, method 2012; MIL-STD-449; and the element

specification.

B.3.3.2.3.1.3 Subgroup 2 (electrical testing). Final electrical testing shall include static tests at 25C, at maximum

rated operating temperature, and at minimum rated operating temperature.

B.3.3.2.3.2 Subgroup 3.

B.3.3.2.3.2.1 Sample size. From each wafer lot, a sample of at least 5 dice requiring 10 bond wires minimum shall

be selected.

B.3.3.2.3.2.2 Wire bond strength testing. For wire bond strength testing:

a.

A minimum of ten wires, consisting of chip to package bonds shall be destructively pull tested. An equal

number of bonds shall be tested on each sample die.

b.

For beam lead and flip-chips, five dice shall be tested.

c.

The die metallization shall be acceptable if no failure occurs. If only one wire bond fails, another sample

shall be selected in accordance with B.3.3.2.3.2.1 and subjected to subgroup 3 evaluation. If the second

sample contains no failures, the bonding test results are acceptable. If the second sample contains one or

more failures, or if more than one failure occurs in the first sample, the lot of dice shall be rejected.

d.

The rejected wafer lot may be resubmitted to A3 evaluation if the failure was not due to defective die

metallization.

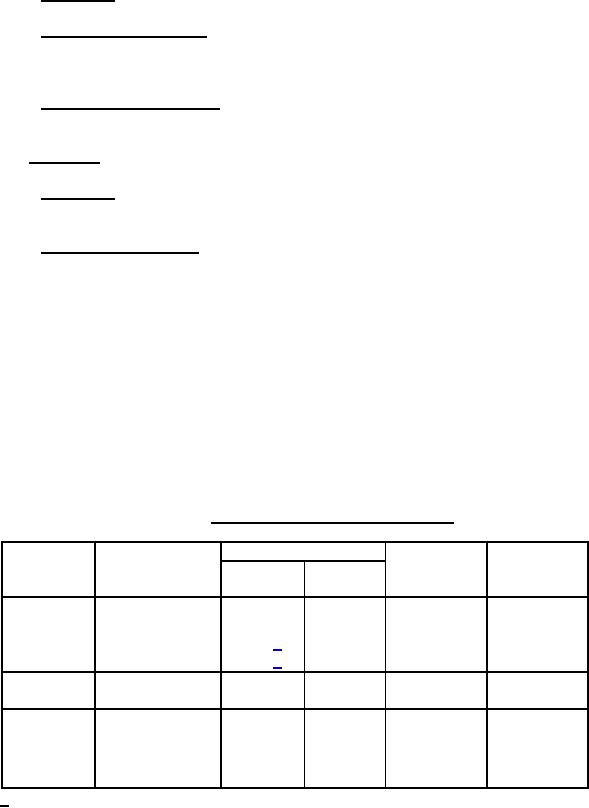

TABLE B-II. Assembled dice evaluation requirements.

Quantity

Reference

Subgroup

Test

Method

Condition

(accept no.)

paragraph

1

Internal visual

2010

As

10 (0)

2072 1/

applicable

2073 1/

2

Electrical

10 (0)

3

Wire bond

2011

As

10(0) wires

evaluation

applicable

or

20(1) wires

1/ MIL-STD-750 methods.

53

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business